In today's digital era, structural integrity checks (SICs) are a cornerstone of quality collision repair. These meticulous assessments go beyond surface-level repairs, scrutinizing every vehicle component—from chassis to body panels—using advanced technology like 3D imaging and CAD software. By ensuring optimal structural soundness, SICs prioritize safety, handling, and the preservation of a vehicle's original specifications and aesthetic appeal, making them crucial for consumers seeking top-tier quality collision repair services.

In the realm of quality collision repair, structural integrity checks are non-negotiable. These meticulous assessments ensure vehicles not only look but also perform like new after an accident. By employing advanced technology and rigorous protocols, technicians can accurately identify and rectify hidden damage, enhancing safety and restoring peace of mind for car owners. This article delves into the significance of these checks, highlighting their pivotal role in delivering top-tier collision repair services.

- Understanding Structural Integrity Checks in Collision Repair

- The Role of Technology in Ensuring Quality and Safety

- Benefits of Rigorous Structural Integrity Assessments

Understanding Structural Integrity Checks in Collision Repair

In the realm of quality collision repair, Structural Integrity Checks (SICs) play a pivotal role in ensuring vehicles return to their pre-accident condition. These checks are not merely a formality but an essential process that validates the structural soundness of every component involved in auto body work, from fender repair to complex frame adjustments. By employing advanced diagnostic tools and hands-on expertise, skilled technicians conduct SICs to pinpoint any misalignments or damage that could compromise the vehicle’s safety and handling.

In light of these checks, vehicle repair services extend beyond cosmetic fixes to encompass a thorough examination of the entire chassis and body panel assembly. This meticulous approach guarantees that every element, including the frame, suspension systems, and various panels like doors, hoods, and fenders (all essential components in auto body work), is accurately aligned and repaired, thereby ensuring optimal performance and safety standards. Understanding the significance of SICs is crucial for consumers seeking quality collision repair services.

The Role of Technology in Ensuring Quality and Safety

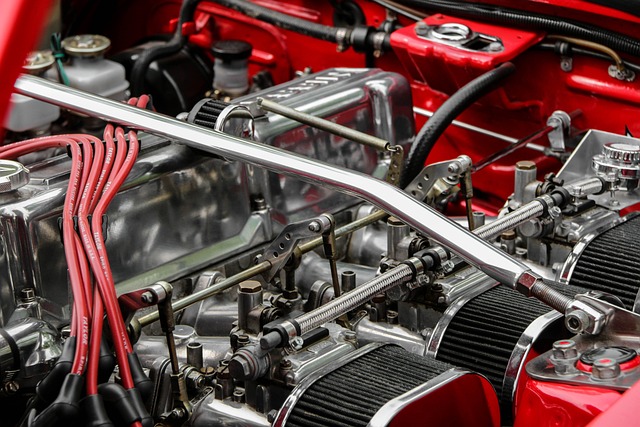

In today’s digital era, technology plays a pivotal role in enhancing quality and safety standards in quality collision repair. Advanced tools like 3D imaging and computer-aided design (CAD) software enable precise measurements and analysis of vehicle structures, ensuring every component is restored to its original specifications. These technologies not only facilitate accurate structural integrity checks but also streamline the entire repair process, minimizing human error and maximizing efficiency.

Additionally, methods such as paintless dent repair leverage modern equipment to remove dents without painting, preserving the car’s original finish and color accuracy. Integrating these technological advancements into auto maintenance routines ensures that every repair meets the highest standards of quality collision repair, guaranteeing both safety and aesthetic appeal for vehicle owners.

Benefits of Rigorous Structural Integrity Assessments

Rigorous structural integrity assessments are a cornerstone of quality collision repair. These thorough checks ensure that every component of the vehicle’s structure is in optimal condition after a collision, from the chassis and frame to the suspension and panels. By identifying even the slightest discrepancies or weaknesses, skilled technicians can prevent future issues and ensure the safety and performance of the vehicle. This process is particularly vital for luxury car brands like Mercedes-Benz, where precision and meticulous craftsmanship are hallmarks of their reputation.

Regular structural integrity assessments during auto maintenance routines also help in extending the lifespan of your vehicle. By catching potential problems early on, repairs can be addressed before they escalate into more costly and time-consuming issues. This proactive approach not only saves money but also ensures that your vehicle body repair is performed with the utmost care and attention to detail, maintaining its original quality and aesthetic appeal.

In conclusion, incorporating structural integrity checks into quality collision repair processes is paramount. These meticulous assessments, coupled with advanced technology, not only ensure the safety and reliability of vehicles but also uphold the highest standards in the industry. By prioritizing rigorous testing, repair facilities can restore vehicles to their pre-accident condition, ensuring customer satisfaction and peace of mind. This practice remains a cornerstone of exceptional quality collision repair.